Importance of Shredders in Tyre Waste ManagemenThe need for shredding

Tyre waste has become a significant environmental concern globally, with millions of tons of discarded tyres posing serious challenges in terms of disposal, environmental impact, and resource utilization. Shredders play a crucial role in tyre waste management by breaking down used tyres into smaller, more manageable pieces. This process has numerous benefits, ranging from resource recovery to environmental protection.

Industrial Heavy duty Tyre Waste Management

Reduction in Volume:

Shredders facilitate the reduction of tyre volume, making it easier to handle, transport, and store. The shredded tyre pieces occupy less space, which is especially important in densely populated areas where land is at a premium. This reduction in volume also helps in minimizing transportation costs associated with moving bulky tyre waste.

Resource Recovery:

Shredding tyres enables the recovery of valuable resources, such as rubber, steel, and textile fibers. These materials can be recycled and reused in various industries, thereby reducing the demand for new raw materials. The recovered rubber, for instance, can be used in the production of asphalt, sports surfaces, or as a raw material for new tyre manufacturing.

Environmental Conservation:

The improper disposal of tyres poses serious environmental threats, including air and water pollution, as well as habitat destruction. Shredders play a crucial role in preventing these negative impacts by breaking down tyres into smaller pieces, making them more amenable to environmentally friendly disposal methods, such as recycling, rather than ending up in landfills. Industrial Heavy duty Tyre Waste Management

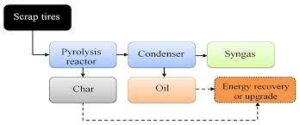

Energy Recovery: Industrial Heavy duty Tyre Waste Management

Shredded tyre pieces can be utilized as a fuel source in various industrial processes, such as cement kilns or power generation plants. This process, known as tire-derived fuel (TDF), not only provides a sustainable energy source but also helps in reducing the reliance on traditional fossil fuels, contributing to a more sustainable energy mix.You may also like to know more about featured products :

Prevention of Illegal Dumping:

The use of shredders in tyre waste management helps prevent illegal dumping, a common problem with bulky waste materials. Shredded tyres are more challenging to dispose of illegally due to their reduced volume, discouraging improper disposal practices and promoting responsible waste management.

Economic Benefits:

Shredding tyres and recovering valuable materials contribute to the circular economy by creating new business opportunities and jobs in the recycling industry. The economic benefits extend beyond resource recovery to include job creation, innovation, and the development of a more sustainable waste management sector. Industrial Heavy duty Tyre Waste Management

Process of Shredding Heavy Duty Industrial Tyre Waste

The process of shredding heavy-duty industrial tyre waste involves several steps, utilizing specialized equipment designed to handle the robust nature of industrial tyres. Here is a brief overview of the typical process: Industrial Heavy duty Tyre Waste Management

Collection and Sorting: Industrial Heavy duty Tyre Waste Management

The first step involves collecting heavy-duty industrial tyres from various sources, such as manufacturing plants, mining sites, or vehicle maintenance facilities. These tyres are then sorted based on size, type, and condition.

Preparation for Shredding:

Before entering in the Industrial Heavy duty Tyre Waste Management shredder, the tyres may undergo some preparation steps. This can include removing any non-rubber components, such as metal reinforcements or textile layers, to ensure efficient and safe processing.

Primary Shredding: Industrial Heavy duty Tyre Waste Management

Industrial Heavy duty Tyre Waste Management, The tyres are fed into a primary shredder, which is a high-powered machine equipped with sharp blades or hammers. This primary shredder breaks down the tyres into large pieces, effectively reducing their size and preparing them for further processing.

Secondary Shredding:

The partially shredded tyre pieces then move to a secondary shredder, which further refines the material into smaller, more uniform pieces. The secondary shredder typically employs more advanced cutting mechanisms to achieve the desired output size.

Granulation:

Industrial Heavy duty Tyre Waste Management, Following secondary shredding, the tyre material may go through a granulation process. This step involves further reducing the size of the shredded pieces into granules or chips of a specific size. The resulting granulated material is easier to handle and can be used for various applications.

Separation and Sorting of Materials:

After shredding and granulation, the mixture of rubber, steel, and textile materials undergoes a separation process. This may involve the use of magnetic separators to extract steel components and other methods to separate different materials, facilitating efficient recycling.

Recycling and Reuse:

The separated materials are then sent to various recycling processes. The rubber can be used in the production of new products such as asphalt, playground surfaces, or even new tyres. The recovered steel is typically recycled and reused in industries requiring metal materials.

Waste Minimization:

The shredding process significantly reduces the volume of heavy-duty industrial tyre waste. The smaller, granulated particles take up less space, making storage, transportation, and further processing more manageable.

Environmental Considerations:

Industrial Heavy duty Tyre Waste Management Throughout the entire process, environmental considerations are crucial. Ensuring proper disposal of any remaining waste and implementing sustainable practices, such as energy recovery from the shredded material, contributes to minimizing the environmental impact of the tyre waste management process.

The role of industrial shredders for Industrial Heavy duty Tyre Waste Management

Industrial shredders play a critical role in the efficient and effective management of heavy-duty industrial tyre waste. These powerful machines are designed to handle the challenges posed by the robust nature of industrial tyres, offering several key benefits in the waste management process:

Volume Reduction:

One of the primary functions of industrial shredders is to significantly reduce the volume of heavy-duty industrial tyre waste. Through a combination of primary and secondary shredding processes, these machines break down large tyres into smaller, more manageable pieces. This reduction in volume facilitates easier storage, transportation, and further processing of the tyre waste.

Resource Recovery:

Industrial Heavy duty Tyre Waste Management, Industrial shredders enable the recovery of valuable resources from heavy-duty industrial tyres. The shredding process separates rubber, steel, and textile components, allowing for the efficient recycling of these materials. Recovered rubber, for example, can be used in various applications, contributing to resource conservation and reducing the demand for new raw materials.

Energy Generation:

Industrial Heavy duty Tyre Waste Management, Shredded tyre waste, particularly the rubber component, can be utilized as a valuable energy source through processes like tire-derived fuel (TDF). Industrial shredders play a crucial role in preparing the material for energy recovery applications, contributing to sustainable energy solutions and reducing reliance on traditional fossil fuels.

Facilitation of Recycling:

Industrial shredders play a pivotal role in the recycling industry by preparing heavy-duty industrial tyre waste for further processing. The shredded material is often sent to specialized facilities where it undergoes additional treatments to produce recycled rubber, steel, and other materials. This promotes a circular economy by incorporating recycled materials into the manufacturing of new products.

Prevention of Illegal Dumping:

The reduction in volume achieved through shredding makes heavy-duty industrial tyre waste less attractive for illegal dumping. Shredded tyre pieces are more challenging to dispose of improperly, discouraging illegal dumping practices and promoting responsible waste management.

Customization for Different Tyre Types:

Industrial shredders are designed to handle a variety of tyre types, including those used in heavy-duty industrial applications. These machines are equipped with robust cutting mechanisms and are customizable to accommodate different tyre sizes and compositions, ensuring versatility in managing a wide range of industrial tyre waste.

Environmental Impact Mitigation:

By breaking down heavy-duty industrial tyres into smaller, more manageable pieces, industrial shredders contribute to mitigating the environmental impact associated with improper tyre disposal. This includes reducing the risk of fire hazards and minimizing the space needed for landfills.

Cost-Efficiency:

While the initial investment in industrial shredders may be significant, the long-term cost benefits are substantial. The efficiency in volume reduction, resource recovery, and potential energy generation contribute to overall cost savings in the waste management process.

Why need Industrial Heavy duty Tyre Waste Management

The need for Industrial Heavy-duty Tyre Waste Management arises from several environmental, economic, and safety considerations associated with the disposal and treatment of large and robust tyres used in industrial applications. Here are some key reasons why effective waste management for heavy-duty industrial tyres is crucial:

Environmental Impact:

Large industrial tyres, if not managed properly, can have severe environmental consequences. Improper disposal methods, such as illegal dumping or inefficient waste management, can lead to soil contamination, water pollution, and habitat destruction. Managing industrial tyre waste helps mitigate these environmental impacts and promotes sustainable practices.

Resource Conservation:

Heavy-duty industrial tyres contain valuable resources such as rubber, steel, and textile components. Effective waste management involves the recovery and recycling of these materials, contributing to resource conservation and reducing the demand for new raw materials. This aligns with principles of a circular economy, where materials are reused and recycled to minimize environmental impact.

Space Utilization and Aesthetics:

The sheer size and volume of heavy-duty industrial tyres make them challenging to store and dispose of properly. Ineffective waste management can lead to visual blight and consume significant amounts of space in landfills. Efficient tyre waste management, through methods like shredding and recycling, reduces the space needed for disposal and enhances the aesthetic appearance of industrial areas.

Prevention of Health and Safety Hazards:

Improperly managed industrial tyre waste poses health and safety hazards. Large tyre piles are susceptible to fire risks, and burning tyres release harmful pollutants into the air. Additionally, stagnant water collected in improperly disposed tyres can become breeding grounds for disease vectors like mosquitoes. Proper waste management minimizes these risks and contributes to a safer working environment.

Compliance with Regulations:

Many countries and regions have regulations and guidelines for the proper disposal and management of industrial waste, including tyres. Compliance with these regulations is essential to avoid legal consequences and penalties. Effective waste management ensures that businesses adhere to these standards and operate in an environmentally responsible manner.

Energy Recovery:

Heavy-duty industrial tyre waste, when processed through methods like tire-derived fuel (TDF), can be used as an alternative energy source. The energy recovery from shredded tyre material contributes to sustainable practices and reduces dependence on traditional fossil fuels.

Economic Opportunities:

Efficient waste management of heavy-duty industrial tyres opens up economic opportunities in the recycling industry. Recovered materials from shredded tyres can be utilized in various industries, creating new business avenues, generating employment, and contributing to economic growth.

Promotion of Sustainability:

Sustainable waste management practices, including the recycling and reuse of heavy-duty industrial tyre waste, align with global sustainability goals. By implementing responsible waste management strategies, businesses contribute to a more sustainable and eco-friendly industrial landscape.